Hola jóvenes lectores. En ese espíritu, veamos cómo puedes cuidar de las bombas de inyección de diesel hoy en día. Si estás familiarizado con los motores diésel, probablemente sabes que la destrucción es causada principalmente por un mal mantenimiento. Muchos vehículos grandes, como camiones y autobuses, están impulsados por motores diésel, lo que los hace funcionar bien. No temas, estamos aquí para explicarte paso a paso cómo cuidar las partes más importantes de tu lavado.

La Importancia del Mantenimiento para las Bombas de Inyección de Combustible Diésel

Ante todo, ten en cuenta que las bombas de inyección de diesel deben ser tratadas con cuidado. Estas bombas son responsables de entregar el combustible al motor y, por lo tanto, son cruciales para su rendimiento. Asegúrate de leer y seguir las instrucciones en el manual de tu motor diésel. Este libro es como una guía; sugiere qué hacer. Es mejor usar combustible diésel de buena calidad según los expertos. Usar combustible de alta calidad ayuda al motor a funcionar mejor y puede incluso extender su vida útil.

Debes asegurarte de que tu Bomba de inyección de combustible diésel es atendido a tiempo. Al igual que vas al médico para revisiones, tu motor diésel también requiere revisiones. Existe alguna parte de la bomba de inyección de combustible que necesita cuidado y mantenimiento. Asegúrate de que estos componentes estén limpios y engrasados para que funcionen como deberían. Limpiar todo desde el principio previene problemas en el futuro.

Soluciones a los Problemas en las Bombas de Inyección Diésel

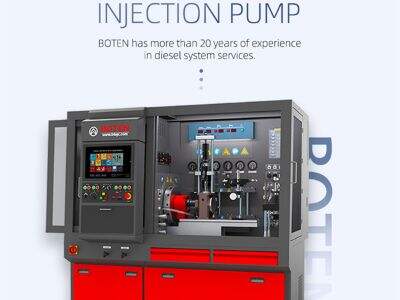

Las bombas de inyección de combustible diésel pueden tener problemas a veces, incluso con un mantenimiento adecuado. Es hora de revisarla si tu motor diésel no funciona como quisieras. Esto puede ser complicado, ya que podrías escuchar ruidos extraños del motor o experimentar dificultades al arrancar. Un mecánico cualificado de Boten debería inspeccionarlo. Ese es el mecánico que no solo sabe cómo reparar motores, sino que también puede ayudarte a entender exactamente qué está mal.

Si tu Bomba de inyección diésel está experimentando problemas, hay cosas que deberías revisar en tu hogar para diagnosticar el problema:

Inspeccione las líneas de combustible en busca de fugas. Algunos de los problemas comunes son cuando las líneas de combustible se desmoronan y fugan, pero la fuga solo ocurre si la línea no está bien sujeta.

Verifique si el filtro de combustible está obstruido. El filtro de combustible evita que la suciedad y los residuos entren en el motor. Si está obstruido, eso puede causar problemas.

Asegúrese de que los inyectores de combustible estén limpios. Los inyectores de combustible atomizan el combustible en el motor. Los inyectores sucios no funcionarán como deberían, lo que puede hacer que el motor funcione mal.

Alargar La Vida De Tu Bomba De Inyección De Combustible Diesel

Ahora que sabes cómo probar tu bomba de inyección de combustible diesel, hablemos de formas de extender su vida útil. Puedes mantener una bomba y motor saludables siguiendo estos consejos:

Cambia el aceite con frecuencia. El aceite mantiene el motor funcionando suavemente, y cambiarlo regularmente puede evitar problemas.

Busque fugas en el sistema de combustible. Si descubre una fuga, debe repararse de inmediato.

Mantén el sistema de combustible limpio. Un sistema de combustible limpio permite que el motor funcione de manera más eficiente, lo que te ahorrará dinero a largo plazo.

Usa combustible de buena calidad. Tu motor funcionará mejor con el tiempo y durará más con combustibles de alta calidad.

Herramientas que podrías necesitar usar para la reparación

Es esencial que antes de poder realmente dar servicio a tu bomba de inyección de combustible diésel, tengas las siguientes herramientas. Estas herramientas incluyen:

Un medidor de presión de combustible. Esta es una herramienta utilizada para verificar si la presión de combustible es correcta.

Un kit de prueba para motores diésel. Este kit te informará si existen problemas con el motor.

Un extractor de inyectores de combustible. Esta herramienta está diseñada para eliminar los inyectores de combustible cuando sea hora de una limpieza o reemplazo.

Con estas herramientas, puedes mantener tus Sistema de inyección de combustible diésel . Ellas te ayudarán a realizar mantenimiento básico y reparaciones.

¿Cómo funcionan los sistemas de inyección diésel?

El mecanismo de funcionamiento del sistema de inyección de combustible necesita ser conocido, después de todo. Hay cuatro componentes clave en este sistema:

El inyector: esta parte rocía el combustible en el motor.

La línea de combustible: Esta es la línea que lleva el combustible del tanque al motor.

La bomba: Este elemento bombea combustible al motor.

El filtro: Este elemento purifica el combustible antes de que entre al motor.

Cuando comprendes cómo estos componentes trabajan juntos, mantener tu bomba de inyección de combustible diésel se vuelve mucho más fácil. Tener toda la imagen en mente facilita mucho reconocer cuándo algo está mal.

Table of Contents

- La Importancia del Mantenimiento para las Bombas de Inyección de Combustible Diésel

- Soluciones a los Problemas en las Bombas de Inyección Diésel

- Alargar La Vida De Tu Bomba De Inyección De Combustible Diesel

- Herramientas que podrías necesitar usar para la reparación

- ¿Cómo funcionan los sistemas de inyección diésel?